Engraving

There are three engraving techniques: mechanical, chemical and laser. In watch making, engraving processes are finishing operations (brand name, model name, serial numbers, the “Swiss made” label) or decorative operations (surface texturing, patterns or designs in slight relief).

Chemical etching

Chemical etching is a complex four-step process. The first is to prepare the parts by applying a protective layer called the "resist” by electroplating. This protection is then removed by laser at the places intended to be etched. The part is finally immersed in baths of corrosive agents, so that the material left unprotected is corroded. Finally, the protective layer of resist applied in the first stage is washed out using galvanic baths, restoring the parts to their original appearance.

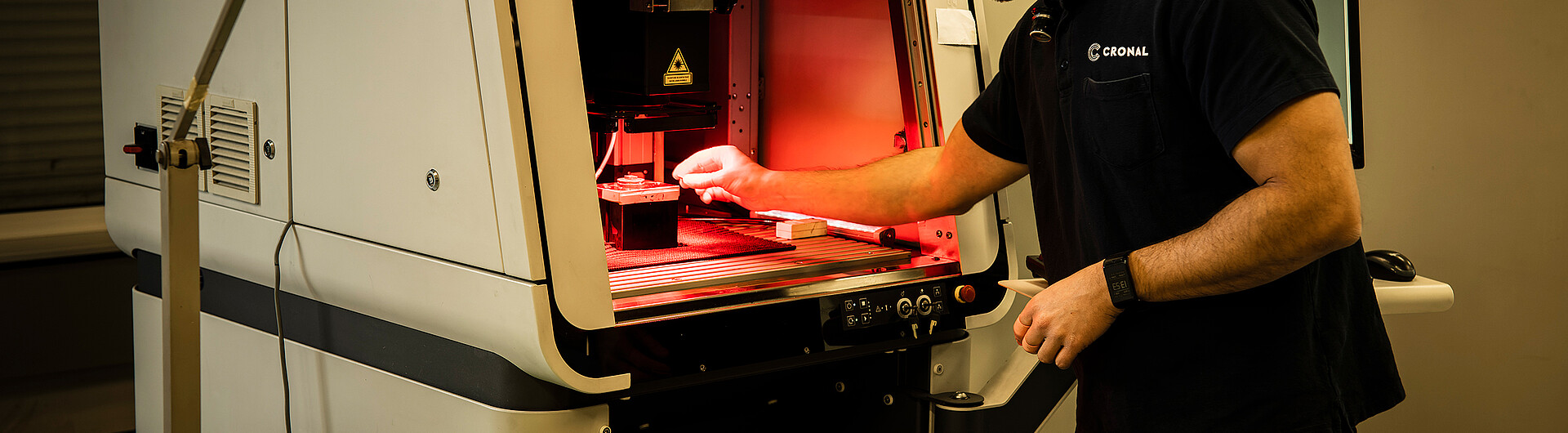

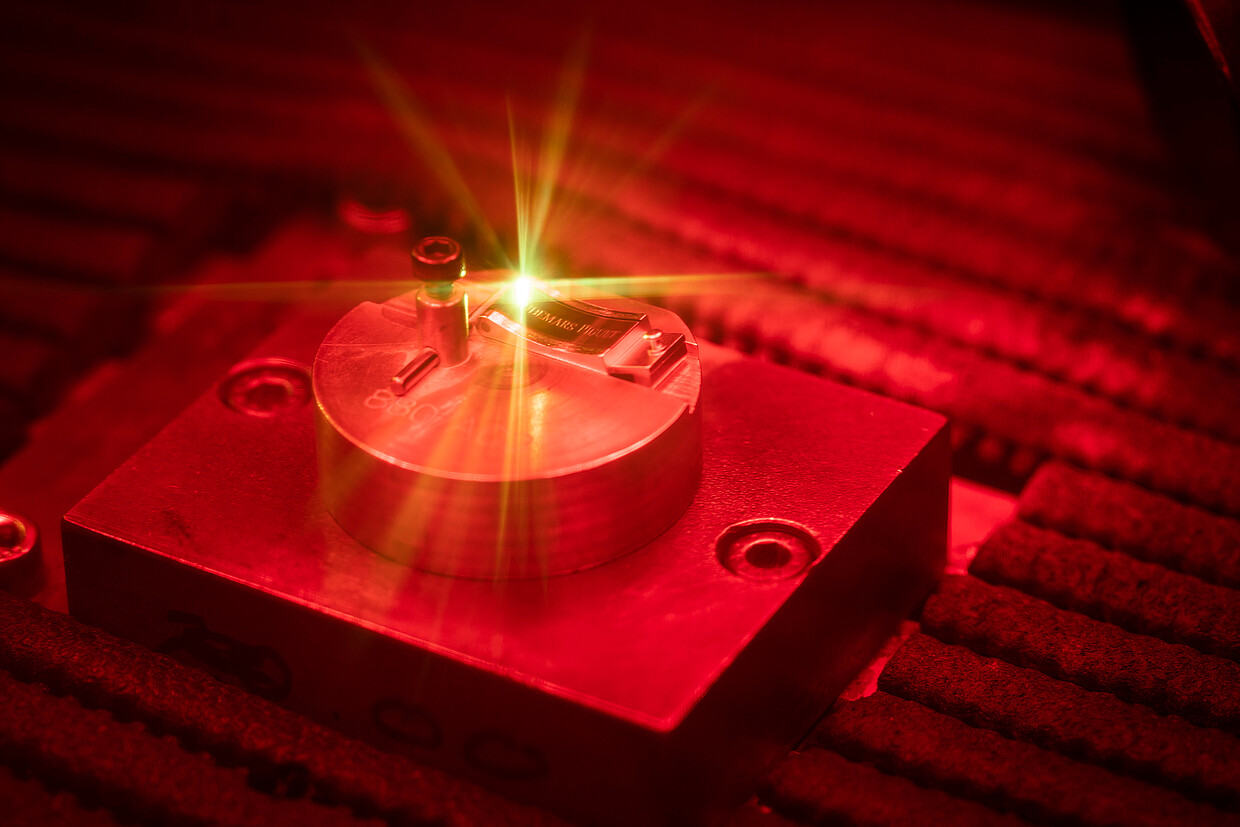

Femtosecond laser

With this engraving technique, the surface of the parts is engraved using only ultrashort pulse lasers (working in femtoseconds). The advantage is that it is able to obtain very precise textures, such as matt, sandblasted or granular surfaces, without causing heat or burning.

We offer

- Perfect knowledge of precious metals and chemicals

- Strict compliance with safety standards for people and the environment

- For chemical etching: high corrosion resistance, which improves electrical conductivity

- For the femtosecond laser: a technique that is perfectly suited to small production series with special aesthetic requirements

- Continuous inspection of each part using microscopes and magnifying glasses that ensure a flawless condition