Machining

The Cendres+Métaux Group’s state-of-the-art fleet of machines combines high-performance digital controllers for machining components with conventional manual equipment that, when linked to the skills of our precision technicians, ensure optimal flexibility for all types of parts and all production run sizes. The inspection equipment present within all workshops is a further guarantee of impeccable quality.

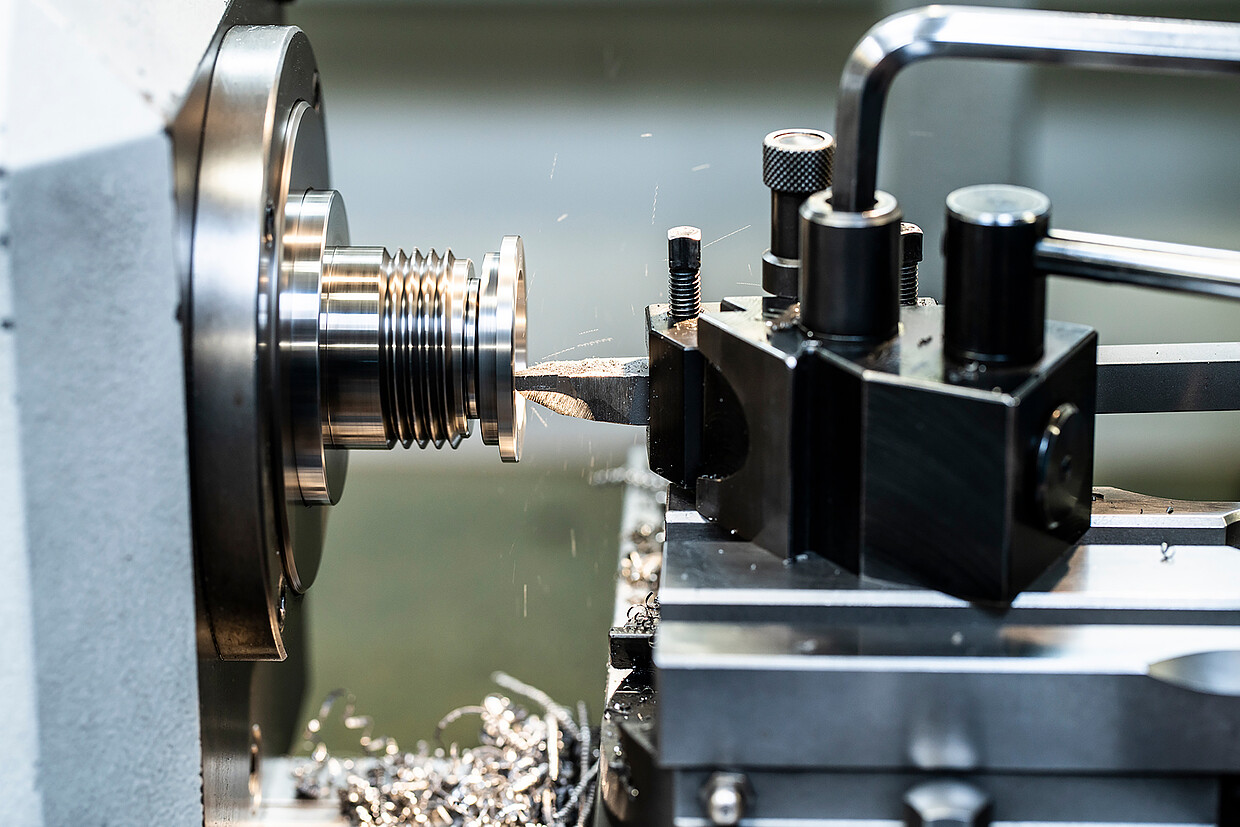

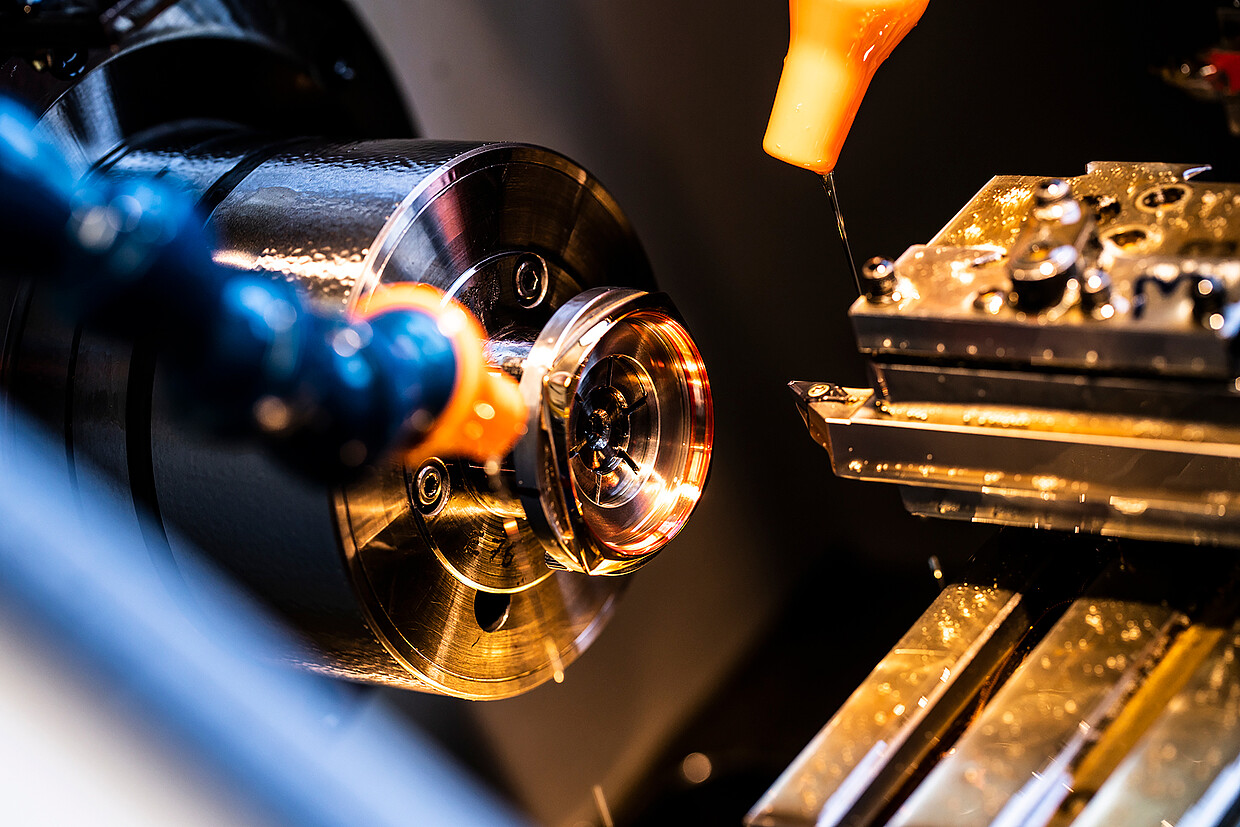

Turning

Turning makes it possible to carry out hollowing operations on parts such as middles, bezels, casebacks or rings (Biel/Bienne site); the technique also makes it possible to form oscillating weights made of precious metals (Biel/Bienne site), as well as middles, bezels, casebacks and rings (Queloz SA).

Milling

Milling is used for hollowing precious metal parts (Biel/Bienne site), machining components such as oscillating weights and precious metal bracelet links (Biel/Bienne site), watch case elements (Queloz SA) and buckle and strap components (Cornu & Cie SA).

Automatic turning

Automatic turning is an automatic machining process involving turning and material removal. It is used to fabricate turned parts starting from a bar or rolls of metal wire. This technology makes it possible to produce components measuring from 0.01 mm to 16 mm in diameter, for both watch movements (screws, pins, wheels) and exteriors (crowns) (Lauener SA).

We offer

- A state-of-the-art machine fleet

- Hyper-precision technologies

- Outstanding quality thanks to continuous inspection